-

KELEI Copana Robotic Welding System

Sistimi ea Copana ke tharollo ea morao-rao ea liroboto ea KELEI e nang le likarolo:

1. Theknoloji ea morao-rao

2. Boleng bo phahameng ba laser

3. Phetoho e sebetsang hantle ea motlakase-optic

4. Sesebelisoa sa welding se ikhethileng

5. Ts'ebetso ea botsoalle ea mosebelisi

6. Khoutu e loketseng

7. Fetola letheba laser sebopeho

-

KELEI Handheld Laser Welding Torch

Sebopeho:

1. KELEI e ikemetseng ea R&D sehlahisoa se faneng ka litokelo tse 14

2. Ho feta 40% sekhahla sa phetoho ea motlakase-optical

3. Likopo holim'a lisebelisoa tse fapaneng

4. Fetola tjheseletsa bophara e leng loketseng bakeng sa basebedisi ba

5. E lumellana le fiber ea limithara tse 10 e ka thusang ho cheselletsa sebaka se selelele

6. Linomoro tsa mekhoa ea mosebetsi li ka ikamahanya le maemo leha e le afe le ho rarahana

7. Liloko tse ngata tsa tšireletso bakeng sa ts'ireletso ea ho sebetsa

-

KELEI Thunderbolt Torch Cleaner

Sebopeho:

1. Ho fana ka tlhoekiso e nepahetseng le e sebetsang bakeng sa boholo ba liroboto tsa litšepe

2. Seha se seholo sa terata esita le tlas'a maemo a thata a ho sebetsa

3. Mokelikeli oa anti-splash o ka fokotsa ts'ebetso ea welding splash mme oa fokotsa tlhoko ea tlhokomelo

4. E fokotsa li-welding slag tse thusang ho fokotsa tlhoko ea tlhokomelo le ho lelefatsa nako ea tlhokomelo

5. Likarolo tsa ho beha maemo le ho seha terata moo mochini o sehang mohala o ka sebetsang ka nepo le ka mokhoa o se nang sekoli

6. Netefatsa hore toche e maemong a eona a matle ka ho atolosoa ka mokhoa o hlakileng le flash-over.

7. Likarolo tse khethiloeng tsa ho hloekisa li ka sefa ka katleho oli, metsi le litšila ka har'a potoloho ea khase, e leng ho ntlafatsang bophelo ba tšebeletso ea lisebelisoa ka kakaretso.

8. Tšebeliso ea li-reamers tse khethehileng le li-blades tsa terata tse boima bo phahameng, le boima bo matla, tse nang le theknoloji ea ho tiisa ente ea oli le ho itšeha ka terata ka mokhoa o itekanetseng, ho ntlafatsa haholo ho tšoarella le boleng ba ho kuta ba thepa.

-

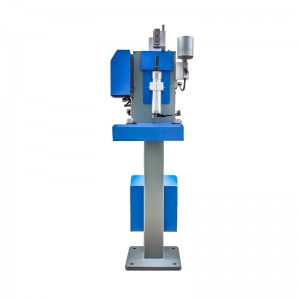

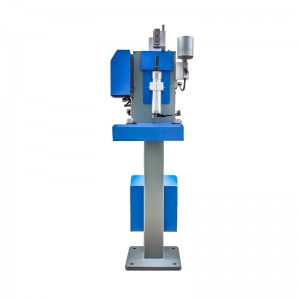

KELEI Box Welding Station

Sebopeho:

1. Ho tjheseletsa ka tsela e iketsang mohatong o le mong o nang le ho sotha ho fokolang le ho sebetsa ka morao, ho tsamaellana le botenya ba 0.5-5mm

2. Mekhahlelo e behiloeng esale pele e ka tlatsa lebokose la tjheseletsa ho fihlela bophara ba 800mm

3. E loketse bakeng sa lihlahisoa tse tloaelehileng tse hlahisoang ka bongata

4. E sebetsa ho liindasteri tsa matla a tsitsitseng, ts'ebetso ea litšepe, motlakase, terene joalo-joalo

5. Likhetho tse fapaneng tsa tlhahiso ea laser ho fihlela ho 2kW

-

KELEI Aeolus Handheld Laser Cleaning Machine

Sebopeho:

1. Mochini oa ho hloekisa o fumaneha ka laser diode tsa 1kW, 1.5kW le 2kW

2. ka lihlooho tsa ho hloekisa tsa KELEI, mokhoa oa ho hloekisa o sebetsa ka 5-10x ho feta ha o bapisoa le lihlahisoa tsa congeneric

3. E loketse hantle bakeng sa ho sebetsana le lihlahisoa tse kholo le tse hlahisoang ka bongata

4. E sebetsa bakeng sa liindasteri tsa matla a tsitsitseng, tlhahiso ea likoloi, ts'ebetso ea tšepe, motlakase, terene joalo-joalo.

5. Tšireletso ea maemo a mangata + k'habinete e thibelang kutu, moralo o ikhethang oa moea, le ho senya mocheso o sebetsang hantle ho eketsa nako ea ts'ebetso ea sehlahisoa sa rona.

6. Theknoloji e tsoetseng pele ea ho hloekisa laser ea pulse e fana ka tlhoekiso e sa senyeheng e sa bakiseng tšenyo ea substrate.Hloekisa ka katleho pente e ka holimo, oli, mafome, filimi ea oxide le litšila tse ling tse tloaelehileng holim'a thepa.

-

KELEI Robotic Laser Seha Hlooho

Sehlahisoa sena se nka monyetla oa ho feto-fetoha ha maemo le motsamao o potlakileng oa liroboto tsa indasteri le ho ts'oana le lisebelisoa tsa morao-rao le lisebelisoa tsa phetiso ea optical.Sehlahisoa se sebelisa theknoloji ea laser ea fiber ho theha mekhahlelo e fapaneng ea ts'ebetso bakeng sa botenya bo fapaneng ba poleiti ha se ntse se etsa seha se nang le mahlakore a mangata ho fihlela litlhoko tsa tlhahiso.E le ho netefatsa ts'ebetso e bonolo le boiphihlelo ba mosebelisi, k'hamphani ea rona e fana ka lits'ebeletso tsa debugging tsa inthanete / ntle le marang-rang ho rarolla matšoenyeho a hau nakong ea ts'ebeliso ho isa tekanyong e kholo.

-

KELEI Robot-sebelisa Laser Welding Torch

Selelekela sa Sehlahisoa:

KELEI Laser e tsepamisitse maikutlo ho khatelo-pele ea mahlale a bohlokoa a ntlafalitsoeng ho tsoa ho boitseanape ba rona bo seng bo etelletse pele indastering.Lilemo tsa lipatlisiso tse matla li thehile sistimi ea rona ea Copana Robotic Welding.Ka maitemogelo go tšwa go boitseanape jwa rona jwa diporojeke tse di humileng, maitemogelo a intaseteri, R&D le bokgoni jwa go dira, re itebagantse le go tsweletsa didirisiwa tsa boitemogelo le tse di botlhale tsa maemo a a kwa godimo tse di tla thusang bareki ba rona go fitlhelela go feta le go tlhwatlhwa e e kwa tlase.

Laser e hlahisoa ke laser mme e fetisoa ka tsela ea kantle ea optical.Ka mor'a ho tsepamisoa ke seipone se tsepamisitseng maikutlo ka har'a motsoako oa welding, se sebetsa ho weld pakeng tsa lisebelisoa tse lokelang ho sebetsoa.Ka thuso ea khase e sireletsang (ho thibela thepa hore e se ke ea e-ba oxidized), lisebelisoa li qhibiliha ho etsa letamo le khethehileng le qhibilihisitsoeng, e le ho finyella morero oa ho cheselletsa.

-

KELEI Thor Handheld Laser Welding Machine

Likaroloana:

1. Mochini oa welding o fumaneha ka laser diode tsa 1kW, 1.5kW le 2kW

2. Seam se tjheseletsang se makhethe se nang le ho sotha bonyane, se loketseng ho tjheseletsa ka botenya ba 0.5-5mm

3. Lihokelo tsa boikhethelo bakeng sa welding ea laser ea autogenous, welding ea laser e tlatsang terata, le brazing ea laser.

4. Sebelisana 'moho le liroboto tsa indasteri tseo ka kopanelo li tlisang bokhoni le bonolo ba likarolo tse rarahaneng tse hlahisang ka bongata le tse boholo bo boholo.

5. E sebetsa bakeng sa liindasteri tsa matla a tsitsitseng, tlhahiso ea likoloi, ts'ebetso ea litšepe, motlakase, terene joalo-joalo.

6. Sebaka se amehileng ke mocheso se senyenyane nakong ea ho cheselletsa, e ke keng ea hlahisa deformation, blackening, kapa trace holim'a workpiece, 'me botebo ba welding bo lekane, welding e tiile,' me ho qhibiliha ho ngata.Liphetho tsa welding li tla ba makhethe 'me li hloeke ntle le deformation kapa khatello ea maikutlo.

7. Sehlahisoa se sebelisa mokhoa oa ho laola o ikemetseng, li-optics tse phahameng tsa threshold, li-lock tse ngata tsa tšireletso, li-coolers tsa metsi, le moralo oa ergonomic.Likarolo tsena li ntlafatsa haholo liphetho tsa welding, li eketsa polokeho le botsitso ba lisebelisoa, li ntlafatsa boiketlo ba basebelisi, li fokotsa mokhathala oa mosebetsi, 'me li eketsa lihora tsa mosebetsi.

Thepa ea ho tjheseletsa laser e tšoaroang ka letsoho e 'nile ea sebelisoa haholo ho cheselletsa lisebelisoa tsa tšepe e sa hloekang, aluminium, koporo le tšepe e' ngoe.Bakeng sa kopo holim'a valve ea kgutlotharo, li-sensor, mechine, lijana tsa tšepe, lisebelisoa tsa phala ea tšepe le tšimo e 'ngoe ea ho tjheseletsa lakane, mokhoa oa ho tjheseletsa oa laser ke mokhoa oa phetoho oa ho sebetsa.

-

Sesebelisoa sa Welding: KLPZ-O2 Nozzle

Nozzle e khethiloeng bakeng sa mochini oa welding oa laser oa KELEI Thor

-

Sesebelisoa sa Welding: KLPZ-Y2 Nozzle

Nozzle e khethiloeng bakeng sa mochini oa welding oa laser oa KELEI Thor

Welding Nozzle bakeng sa tjheseletsa ea laser e tšoaroang ka letsoho

Premium Copper/ Mocheso le slag resistance/ Likhetho tse felletseng tsa boholoTs'ebetso e kholo le ho tšoarella

Fine machining/ Ho hanyetsa mocheso le letlapa

High Hardness, phahameng mocheso hanyetsa le phahameng conductivity

Bokaholimo bo fetisoa ho fokotsa ho khomarela ha slag e fofang, ho qeta ho boreleli ho netefatsa botsitso ba matla a tlhahiso.

-

Ho seha ha Laser ea Robotic

1. Ho laola habonolo, ka lebaka la tekanyo e phahameng ea bohlale ba tsamaiso

2. Ho ikamahanya le maemo ho phahameng le ho feto-fetoha ha maemo ho li-workpieces

3. Liphetho tse tsitsitseng tsa ho itšeha le boleng ba tlhahiso

4. Lebelo le phahameng, ho nepahala, le ho tšepahala