KELEI Copana Robotic Welding System

Tlhaloso ea Sehlahisoa

Ka tsoelo-pele ea mahlale a khomphutha, thekenoloji ea marang-rang, litsamaiso tse bohlale tsa taolo, bohlale ba maiketsetso le litsamaiso tsa tlhahiso ea indasteri, liroboto tsa welding li tla khona ho tjheseletsa, ho sebetsa ka tšepe le liindasteri tse ling.Ho tsitsa ha eona, tlhahiso le boleng ba ho tjheseletsa li phahametse ho cheseletsa ka letsoho ha liroboto li ka fokotsa matla a basebetsi.Ntle le moo, liroboto li khona ho sebetsa libakeng tse kotsi, 'me litšenyehelo tsa tsona tse tlase tsa ho koetlisa, ho sebetsa le ho li hlokomela li etsa hore e be khetho e ke keng ea qojoa ea ho cheselletsa nakong e tlang.

Sehlahisoa sena se nka monyetla oa ho feto-fetoha ha maemo le motsamao o potlakileng oa liroboto tsa indasteri le ho ts'oana le lisebelisoa tsa morao-rao le lisebelisoa tsa phetiso ea optical.Sehlahisoa se sebelisa theknoloji ea laser ea fiber ho theha mekhahlelo e fapaneng ea ts'ebetso bakeng sa botenya bo fapaneng ba poleiti ha se ntse se etsa seha se nang le mahlakore a mangata ho fihlela litlhoko tsa tlhahiso.E le ho netefatsa ts'ebetso e bonolo le boiphihlelo ba mosebelisi, k'hamphani ea rona e fana ka lits'ebeletso tsa debugging tsa inthanete / ntle le marang-rang ho rarolla matšoenyeho a hau nakong ea ts'ebeliso ho isa tekanyong e kholo.

Likaroloana

1. Laser ea boleng bo phahameng: matla a laser a matla a hlahisa liphetho tse ntle tsa welding tlas'a maemo a tšoanang ha a bapisoa le lihlahisoa tse ling.

2. Ho sebetsa ka mokhoa o phahameng: mokhoa o sebetsang oa ho fetola matla oa tsamaiso o ka holimo ho 40% e senyang matla a fokolang.

3. Theknoloji e tsoetseng pele: "Bull's Eye" e etellang pele indastering ea laser spot mode e khaolang / weld ka potlako le ho hloekisa.

4. Ho tšoarella nako e telele: likarolo tsa mantlha li na le melao-motheo e sa hlokahaleng ea ho itokolla kelellong e ka etsang liteko le litekanyetso tse tiileng.

5. Ho bonolo ho sebetsa le ho ithuta: laser le roboto hlokomela puisano ea digital.Laser ea Kola ha e hloke taolo e eketsehileng ea k'homphieutha, empa e ka laoloa ke molaoli oa robot.Hore na ke ho hlophisoa ha matla a laser kapa khetho ea tsela e arohaneng ea leseli, tšebeliso e mpe kapa karabo e fosahetseng e ka qojoa.Molaoli oa liroboto a ka laola roboto, hlooho ea laser le laser habonolo, a eketsa ts'ebetso ea lisebelisoa.

Tlhaloso

Roboto

| Mohlala oa roboto | TM1400 | |||

| Mofuta | Khokahano ea li-axis tse tšeletseng | |||

| Boholo Mojaro | 6Kg | |||

| Letsoho | Max Finyella | 1437 limilimithara | ||

| Min Reach | 404 limilimithara | |||

| Finyella Range | 1033 limilimithara | |||

| Kopanetsoeng | Letsoho | ( RT axis) | Front Baseline | ±170° |

| (UA axis) | Motheo o otlolohileng | -90°~+155° | ||

| (FA axis) | Horizontal Baseline | -195°~+240°(-240°~+195°)※ | ||

| Forearm Baseline | -85°~+180°(-180°~+85°)※ | |||

| Letsoho | (RW axis) | ±190° (-10°~+370°)※ | ||

| (BW axis) | Bend Wrist Baseline | -130°~+110° | ||

| (Tlhaloso ea TW) | Tšebeliso ea Cable ea Kantle: ± 400 ° | |||

| Lebelo le Leholo | Letsoho | (Tlhaloso ea TW) | 225°/s | |

| (UA axis) | 225°/s | |||

| (FA axis) | 225°/s | |||

| Letsoho | (RW axis) | 425°/s | ||

| (BW axis) | 425°/s | |||

| (Tlhaloso ea TW) | 629°/s | |||

| Ho Nepaha Ho Phethahetseng | ± 0.08mm Boholo ba 0.08mm | |||

| Mohloli oa boemo | Coder ea mesebetsi e mengata | |||

| Motor | Kakaretso ea Matla a ho Khanna | 3400w | ||

| Mokhoa oa ho senya | Li-brake li kopantsoe ka mahlakoreng 'ohle | |||

| Ho thethefatsa | Sehlopha sa D kapa ka holimo bakeng sa liroboto | |||

| 'Mala oa ho penta | RT Base boemo: munsell: N3.5; Maemo a mang: munsell: N7.5 | |||

| Ho kenya | Fatšeng kapa siling | |||

| Mocheso/mongobo | 0℃~45℃,20%RH~90%RH 【Temp=40℃时,Mongobo≤50%RH(Ha ho condensation);Temp=20℃,Mongobo≤90%RH(Ha ho condensation)】 | |||

| Lintlha tsa IP | IP40 e lekanang | |||

| Boima ba 'mele | Hoo e ka bang 170 | |||

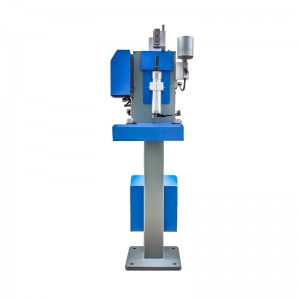

1. Mochini oa welding oa Laser: bua ka matla a tšoanang a KRA laser welding machine

2. Laser welding gun: bua ka hlooho ea laser cut ea robot ea Keradium e nang le matla a tšoanang